Novoloop says it’s worked out how to upcycle plastic waste, raises $11M Series A

Upcycling polyethylene (the normal ubiquitous plastic we are all familiar with) into high-value plastics that can compete with “virgin” plastic (meaning plastics made directly from petro-chemicals) is a fiendish problem to solve. The fact that it’s been extremely hard to do so means billions of tonnes of plastic is never recycled, and it’s out there pouting the […]

Upcycling polyethylene (the normal ubiquitous plastic we are all familiar with) into high-value plastics that can compete with “virgin” plastic (meaning plastics made directly from petro-chemicals) is a fiendish problem to solve. The fact that it’s been extremely hard to do so means billions of tonnes of plastic is never recycled, and it’s out there pouting the planet and our oceans. A new US-based startup, Novoloop, claims to have come up with an answer.

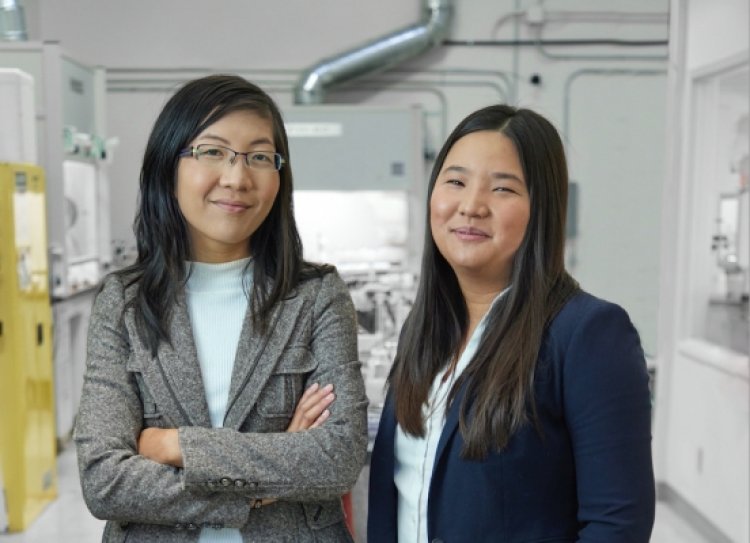

The two female founder scientists, Jeanny Yao and Miranda Wang have been working for over five years on this problem.

They have now raised $11 million in a Series A financing led by Envisioning Partners with participation from Valo Ventures and Bemis Associates; earlier investors who joined the round included SOSV, Mistletoe, and TIME Ventures. Novoloop is also partnering with Bemis Associates, which makes apparel bonding solutions such as seam tapes, which can be found in high-performance outerwear.

Novoloop is setting out to transform plastic waste into high-performance chemicals and materials. The company says it has developed a proprietary process technology it calls ATOD (Accelerated Thermal Oxidative Decomposition). It claims that this breaks down polyethylene (the most widely used plastic today) into chemical building blocks that can be synthesized into high-value products.

(Accelerated Thermal Oxidative Decomposition). It claims that this breaks down polyethylene (the most widely used plastic today) into chemical building blocks that can be synthesized into high-value products.

The first product will be Oistre , a thermoplastic polyurethane (TPU) for use in footwear, apparel, sporting goods, automotive, and electronics. Novoloop claims this has a carbon footprint that is up to 46% smaller than conventional TPUs.

, a thermoplastic polyurethane (TPU) for use in footwear, apparel, sporting goods, automotive, and electronics. Novoloop claims this has a carbon footprint that is up to 46% smaller than conventional TPUs.

Novoloop Co-founder and CEO Miranda Wang said in a statement: “Plastics are not going away anytime soon, so we need to innovate to close the gap between what is produced and what is repurposed. After years of technology development, we’re thrilled to announce backing by high-caliber investors and partners to commercialize this much-needed technology.”

“What really compelled us to lead the investment round is that Novoloop has found product-market fit,” said June Cha, Partner of Envisioning Partners. “Novoloop has proven that Oistre has a wide range of applications in the market even at their early stage.”

Speaking to me over a call, Wang added: “Polyethylene plastic is the most common packaging used but is extremely hard to chemically change and break apart and turn into useful things. We cracked this by essentially adopting a new chemical approach to oxidise this polyethylene.”

“Everybody else is turning this plastic waste polyethylene into fossil fuel reserves. But for us, our approach is to directly take the polyethylene waste and convert it in one step… So this essentially bypasses many steps and chemistries that would otherwise happen if people were to take it back into oil or into gas,” she said.

Competitors to Novoloop would include BASF, Covestro, Lubrizol, Huntsman. These are companies that make virgin fossil fuel-based TPU. About 99% of TPUs are virgin today. In other words, this is a giant industry ready for disruption.